In today’s fast-paced manufacturing world, ensuring product quality and safety is crucial. One of the most effective ways to achieve this is by adhering to Good Manufacturing Practices (GMP). GMP Compliance provides a structured approach to maintain high standards in manufacturing processes, ensuring that the products are consistently produced and controlled according to quality criteria. This blog explores how GMP compliance can safeguard product quality and why it’s critical for businesses aiming to thrive in competitive industries.

What is GMP Compliance?

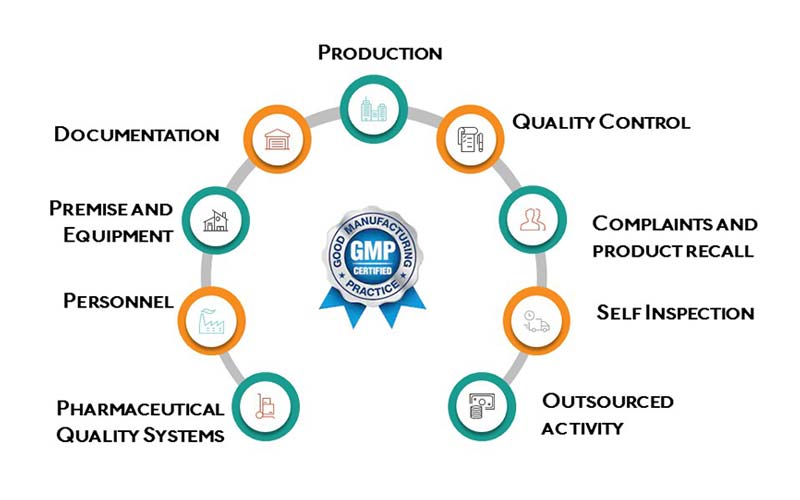

Good Manufacturing Practices (GMP) are a set of regulations enforced by regulatory agencies worldwide. These guidelines cover all aspects of production, from the procurement of raw materials to the handling, manufacturing, and packaging of the finished product. Compliance with GMP ensures that every product is safe for consumers and meets the quality requirements.

GMP standards apply to industries such as pharmaceuticals, food and beverages, cosmetics, and medical devices, where product safety and efficacy are paramount. Companies adhering to GMP guidelines are better positioned to avoid risks such as contamination, mix-ups, and recalls, which could severely impact both the business and consumers.

How Does GMP Compliance Ensure Product Quality?

- Strict Process Control

GMP emphasizes well-documented and controlled processes throughout production. Every step, from sourcing raw materials to final delivery, is monitored and validated. This reduces variations and ensures consistent quality across all batches of products. - Rigorous Testing

Products undergo regular testing at different stages of manufacturing to ensure they meet the necessary quality standards. Raw materials are inspected, in-process controls are maintained, and final products are tested before they reach the market. - Preventing Contamination

GMP includes strict hygiene and sanitation protocols, minimizing the risk of contamination. Clean facilities, proper storage, and trained personnel all contribute to a controlled environment where product safety is prioritized. - Comprehensive Documentation

An essential aspect of GMP is maintaining thorough records. Every batch of a product has a detailed log of its production process, including any deviations or issues. This documentation ensures traceability, allowing companies to quickly address potential problems and make necessary adjustments. - Training and Development

GMP Compliance requires that staff involved in production are well-trained and continuously updated on best practices. This ensures that employees are knowledgeable about maintaining safety and quality standards in their specific roles.

Why is Adhering to GMP Compliance Important?

- Regulatory Requirement

Many industries are mandated by law to comply with GMP regulations. Failure to do so can result in heavy fines, product recalls, or even shutdowns. GMP certification is often a prerequisite to entering global markets, making it essential for business expansion. - Building Consumer Trust

Consumers want to feel confident that the products they use meet high safety and quality standards. GMP-certified companies can showcase their commitment to quality, enhancing brand reputation and building customer trust. - Reducing Costs and Risks

By preventing errors, contamination, and defects, GMP compliance helps businesses reduce the likelihood of product recalls and liability claims. This not only protects the company’s reputation but also saves significant costs in the long term.

Achieving GMP Certification

GMP Certification is awarded to businesses that meet the rigorous standards set forth by regulatory authorities. Achieving this certification involves an extensive audit of manufacturing processes, facility conditions, staff training, and documentation practices.

While obtaining GMP certification requires a significant investment in terms of time and resources, the benefits are invaluable. Certified companies are better positioned to deliver high-quality products, enhance customer satisfaction, and compete in both domestic and international markets. At Skydream Digital Innovations, we provide expert guidance to help businesses meet GMP standards and secure certification.

Conclusion

GMP Compliance is the foundation of product quality and safety in manufacturing. By adhering to Good Manufacturing Practices, businesses can ensure that their products consistently meet regulatory standards and customer expectations. Whether you’re in the pharmaceutical, food, or cosmetic industry, following GMP guidelines and achieving certification can give your business a competitive edge while safeguarding consumer health.

For businesses looking to improve their operations and achieve GMP certification, partnering with industry experts like Skydream Digital Innovations can make the process seamless and efficient. By committing to GMP compliance, you’re not only protecting your business but also ensuring long-term success in a competitive marketplace.